H. Kamerlingh Onnesweg 2

2408 AW Alphen aan den Rijn

Netherlands

Corrugated Flat Mounting Machine

Flatmount

The Flatmount is a premier flat flexo plate mounting machine for mounting on mylars. Mounting with the Flatmount is very fast and, optimizing efficiency while simultaneously reducing costs. Flat mounting is a growing trend in corrugated postprint, and with Flatmount's patented solutions you can obtain rapid and precise mounting.

- 30% Faster than a Round Mounter

- Automatic HD Cameras for an Accurate Mounting

- Quick and Easy Mounting

- Easy Job Creation

- Advanced Options for a Smooth and Faster Workflow

Discover Flatmount

Features

Once the first plate is on the right position, a snapshot can be taken and used semi-transparently for the next plates.

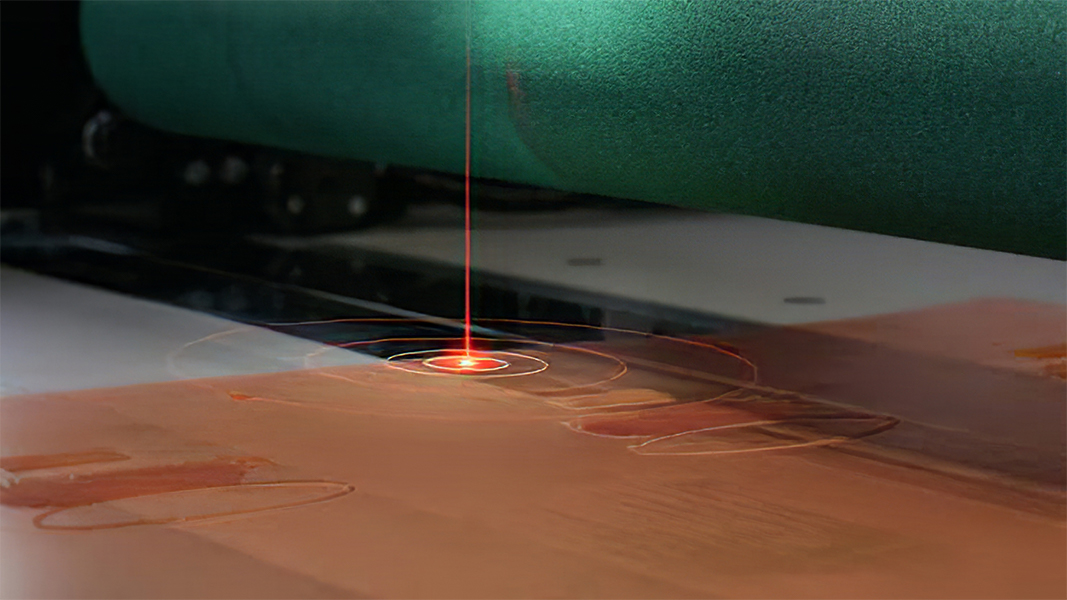

Ultra high definition cameras moving to the exact position of the mounting marks.

The cameras can be controlled by encoders for quick adjustments. The operator can insert commands through the touchpad.

The camera images are used in a calibration procedure to create a lookup table to digitally ‘straighten’ any deviations in the camera beam, down to 10 μm over the entire width of the camera beam/sleeve

Windows 10 icon-based AV Flexologic mounting software for easy job creation and storage. The user interface is optimized to offer the best operator experience.

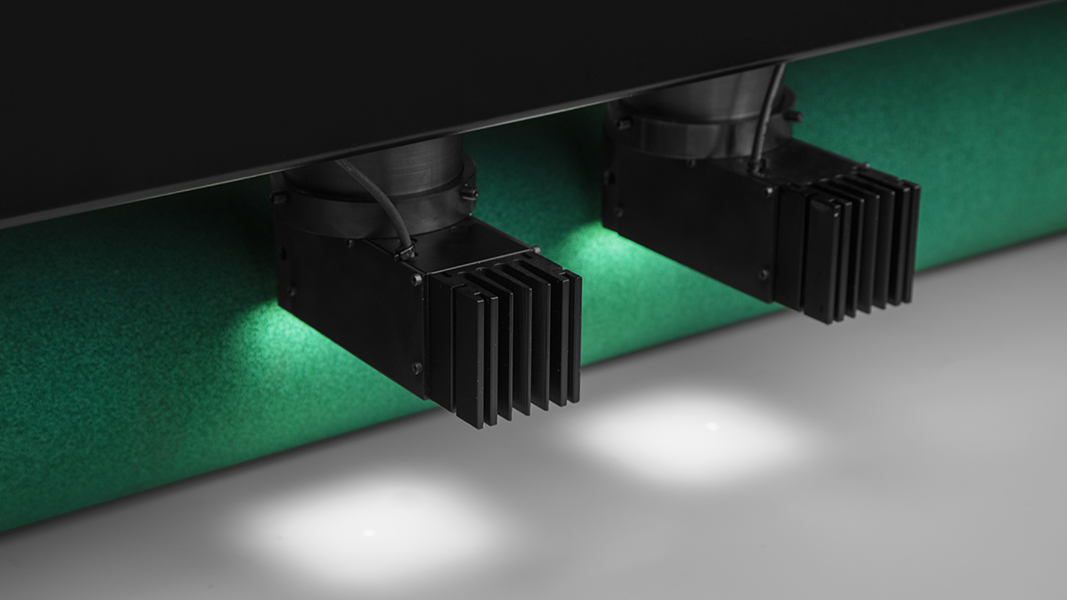

Latest technology DOAL lights for optimal target recognition.

Indicators of where the mounting marks are located for placing easily the plates.

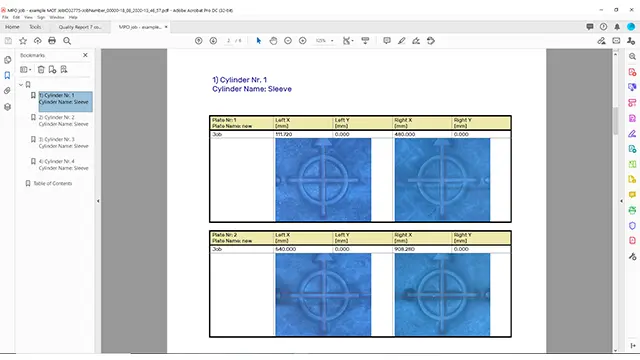

The mounting marks are checked and a PDF is automatically created with the measurements of the Image Recognition.

Success Stories

Contact Our Team

Get in touch with us for any questions about our company or services.

We will do our best to get back to you promptly.

[email protected]

VAT: NL001515561B01

PO Box 252

2400 AG Alphen aan den Rijn

Netherlands