H. Kamerlingh Onnesweg 2

2408 AW Alphen aan den Rijn

Netherlands

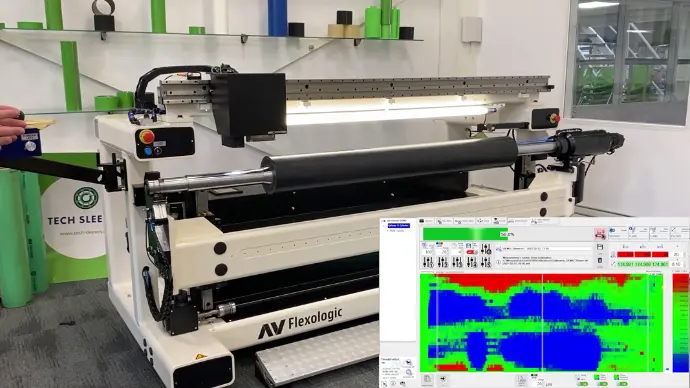

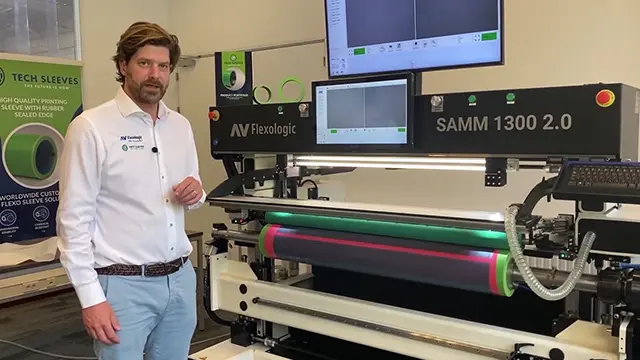

Automatic Mounting Machine

SAMM 2.0

The Automatic SAMM 2.0 is the world’s fastest and most accurate flexo plate mounter with unmatched repeatability and speed. The next generation SAMM is the solution to common trends in the flexo printing industry such as higher quality demands, shorter and more frequent job runs. These challenges are easily tackled with 3rd generation Automatic Mounting.

- Automatic mounting

- Eliminates press downtime due to mounting mistakes

- PDF Quality Report

- Operator independent

- Typical ROI in less than 12 months

Discover SAMM 2.0

Features

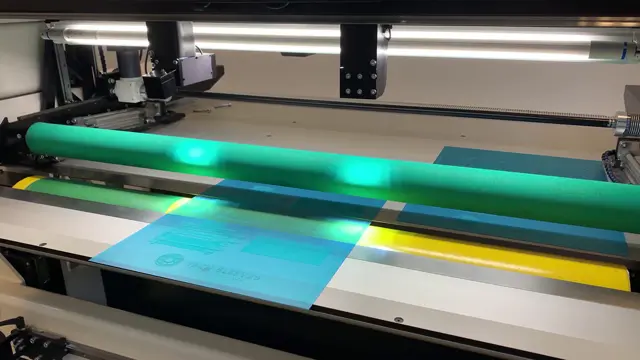

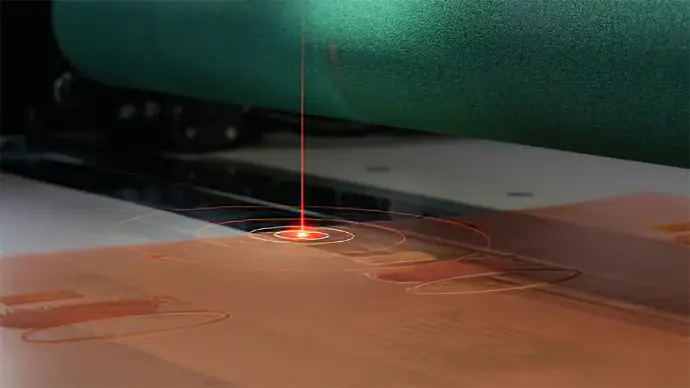

The machine automatically positions the flexo plate with extreme accuracy, using a robotic table and our patented Image Recognition.

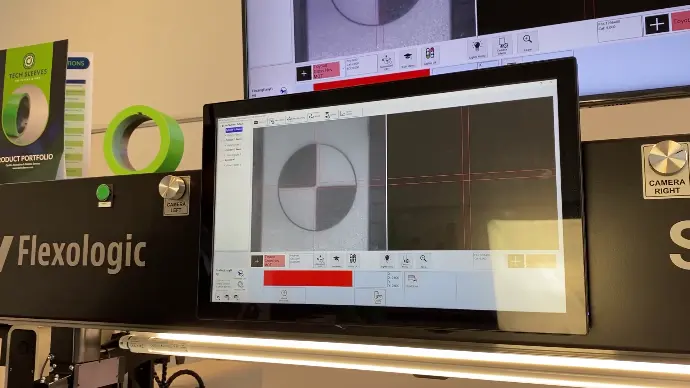

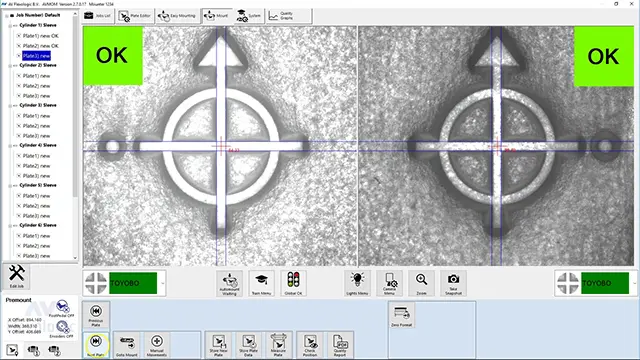

High-definition monochrome cameras that automatically adjust to the precise mounting location.

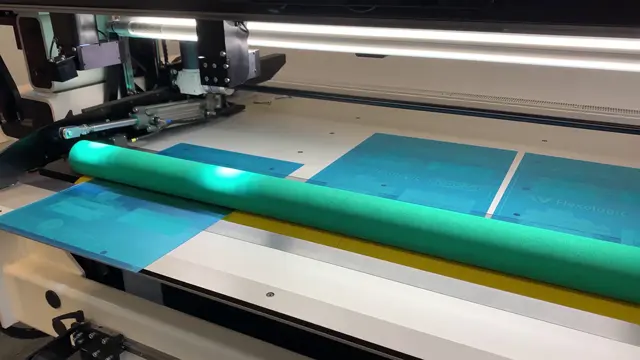

Ensures even mounting without any air inclusions. No operator interaction needed.

Robotic table which provides operator-free mounting

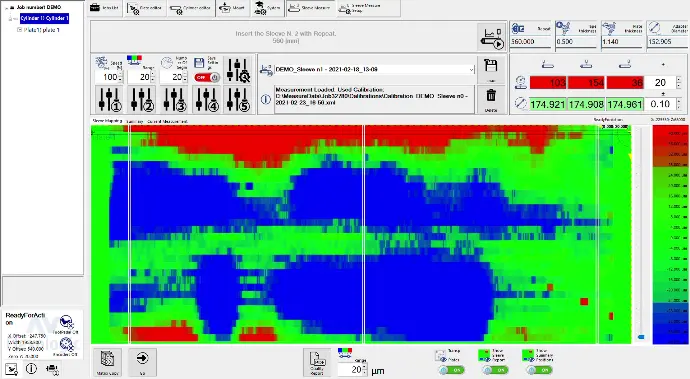

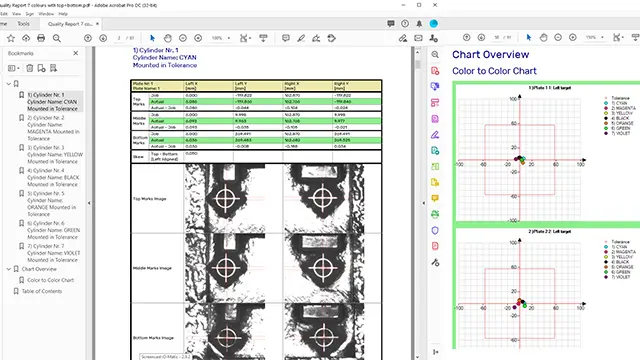

The mounting marks are checked and a PDF is automatically created with the measurements of the Image Recognition.

It allows a fixed distance between the cameras and the plate, so no focusing of the lenses is needed. The cylinder rotates also automatically.

Indicators of where the mounting marks are located for placing easily the plates.

The Easymount software allows easy job creation and storage in less than 1 minute. Using the cameras of the machine, the software recognizes the targets and measures the distance between them.

Range

1300/52'' (mm/inch) Max Width

1350/53'' (mm/inch) Max Repeat

1700/67'' (mm/inch) Max Width

1350/53'' (mm/inch) Max Repeat

2200/87'' (mm/inch) Max Width

1350/53'' (mm/inch) Max Repeat

Business Case

In 2014, a flexo printer located in Europe invested in a SAMM. This organization handles the mounting of approximately 15,000 to 17,000 sleeves each year and runs 3 flexo printing presses. The chart below showcases the improvements the SAMM has brought to the workflow of this facility.

Success Stories

Contact Our Team

Get in touch with us for any questions about our company or services.

We will do our best to get back to you promptly.

[email protected]

VAT: NL001515561B01

PO Box 252

2400 AG Alphen aan den Rijn

Netherlands